WHO ARE WE

Innovators in Plastics & Packaging Technology

SI Protech (UK) Ltd, a leading plastics component manufacturer, aims to be recognised as an innovative and forward-thinking supplier across the industries it serves, with a particular focus on the beverage and brewing sector. Our objective is to be acknowledged not only for our industry insight and customer-driven approach but also as a premier manufacturer of high-quality, technically advanced injection moulded components and assemblies.

Research & Innovation

‘’Research and innovation is an essential part of what SI Protech does triggering inventive and sustainable solutions for our customers’'. By producing new knowledge, research is central to developing new and innovative products, processes and services, which enable our customers to higher productivity and improved competitiveness, and ultimately prosperity.

product development

Development support for those who lack experience with thermoplastics. We offer IP Review, 3D Component Design & Modelling, Fast Prototyping & Material Consultancy services.

Design & Development

“SI Protech (UK) Ltd is your advising partner on material selection, production feasibility, product design, mould manufacturing, assembly Systems and technical packaging solutions.” We provide support to customers with mature products, mature products requiring Improvement or replacement as well as new projects for companies and developers.

manufacturing

We operate within a 28,000 square ft. facility, 5-7 days a week, 24 hours a day. This includes ‘white room assembly’ for food and drink related product assembly. Our manufacturing system is built around prevention rather than detection. We strive to begin with developing a capable process and then maintain during batch production.

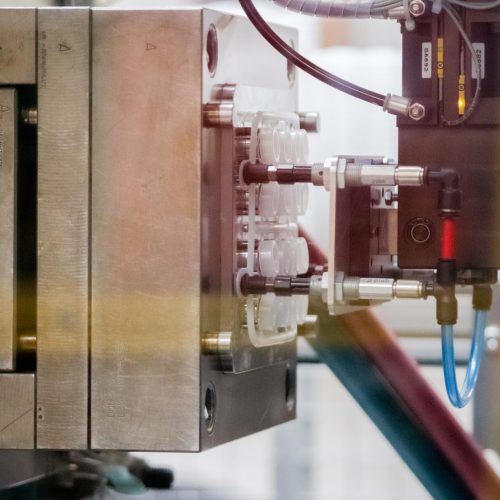

Injection molding

Experts in working with Polymers such as Polypropylene, Polycarbonate, Nylon, LDPE/HDPE, PBT, ABS, PC, SAN, GPPS, TPE TPU, POM and more.

Quality Assurance & Control

Quality is promoted and developed internally using Six Sigma and Lean tools and techniques. All of our Quality Systems are externally validated by the BSI (British Standards Institute to the international standards : ISO 9001 for Quality Management , ISO 14001 for Environmental Management and ISO 22000 Food /Drink Packaging Safety , Hygiene & Security Management

FM 657849

EMS 657848

FSMS 730903

about us

Established in 1998

We have extensive experience in product development, mould tooling, plastic injection moulding, and final production. As a plastics component manufacturer, the company serves a range of markets including the Beverage, Pharmaceutical, Personal Care, and Automotive industries.

As a technical injection moulding company, we specialise in high-specification manufacturing products and solutions, and can therefore advise on material selection, production feasibility, mould design, packaging, and more during the crucial product development stage.

SI Protech serves customers across the South and South East of England, as well as UK-wide and internationally.

our mission

Reputation is Key

SI Protech (UK) Ltd has built a great name within the markets it serves.

Highly regarded as an innovative and high quality design, development, injection moulding and assembly company in our multinational and UK market sectors.

Working with many leading companies including Heineken, Anheuser-Busch InBev, Colep, Parker Hannifin, Honeywell and more…

Our Team

The management team are all experienced and fully qualified in their individual fields, working together to serve our customers and to propel the company forwards.

Vasco Miguel

Managing Director

Alan Edmonds

Non exec Director

Mark Sillince

R&D director & founder

Neil Cranfield

finance

director

Stewart Ray

Technical

Manager

Paula Felico

Quality Manager

Kanchan Sanyal

Sales Agent Midlands/North

Peter White

Sales Agent South/West

Mitchell Joseph

MAJORITY SHAREHOLDER

Our Products

Customer Feedback

"Sl-Protech is a very technical and quality orientated company. In the financial and purchasing department of production materials, there is still some improvements to be made.

"Very satisfied with the level of service and high quality of mouldings, we do sometimes see issues but these are always quickly resolved."

"Thanks for all your help with our sometimes vague and often urgent requests"

"Contacts are friendly. Always an answer to my questions. Very responsive".